The two main qualities that all of the highly skilled sheet metal workers i have worked with possess are knowledge and patience.

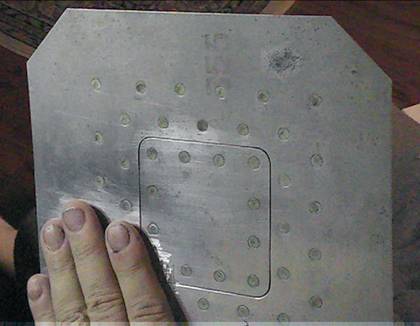

Airplane sheet metal circular patch template.

So i will draw a line 1 4 from the small hole and inward from the outline of the patch i drew.

You will often find a crack developing in an area such as an engine cowling.

Maintain the original strength.

The reader should be familiar working with sheet metal and riveting.

A rounded or several sided patch is preferable over a square patch.

Make a template using paper.

I then used the templates to trace out the patch panels on some sheet metal.

The primary objective of aircraft repair is to restore damaged parts to their original condition.

Cut out a circular patch from a sheet of aluminum that is the same thickness and the original aircraft skin.

After slicing the patches out with a cutoff wheel next came the bending hammer and dolly session until the patches matched the holes and fit snug and flush into the flanged seat.

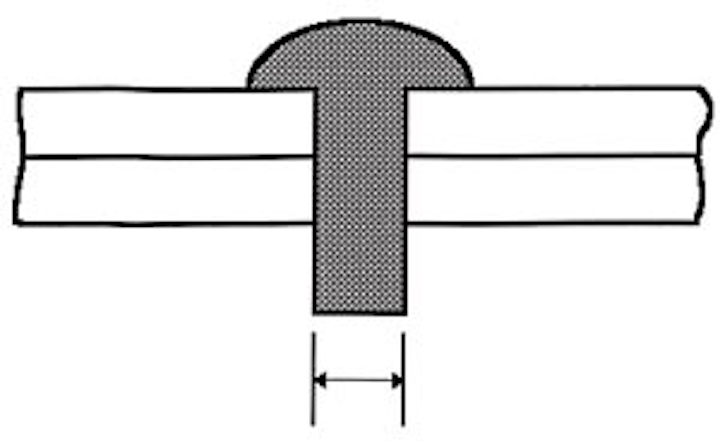

The patch plate should have a cross sectional area equal to or.

At the lower speeds then obtainable streamlining was not a primary consideration and many wires struts braces and other devices were used to provide the necessary structural strength.

Airplane airplane materials and construction.

Use advisory circular ac43 13 1b as a reference to determine proper rivet layout for the patch.

Select the appropriate material.

For reasons of availability low weight and prior manufacturing experience most early aircraft were of wood and fabric construction.

If you re not sure how to approach a repair get the assistance of a qualified aviation sheet metal mechanic.

Knowledge comes from learning all of the factors that affect good.

Keep the weight to a minimum prem mahendranathan.

Maintain the original strength.

This is a very common problem on sheet metal airplanes.

Another excellent source is aircraft sheet metal published by jeppesen.

Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one.

Cutout the corners into oval or circular shape.

I used a piece of pvc pipe a vice mount miniature metal break and body hammer kit.

Learn how to bend sheet metal so you.

In all cases your primary reference for all repairs is faa advisory circular 43 13 1b acceptable methods techniques and practices aircraft inspection and repair.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.