Nucor skyline supplies a wide variety of sheet pile from leading manufacturers.

Allowable bending stress steel sheet pile.

Design moment would be considered equivalent.

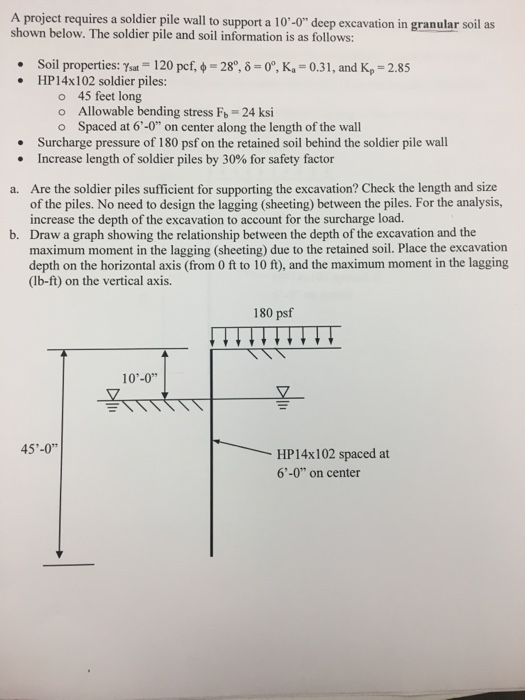

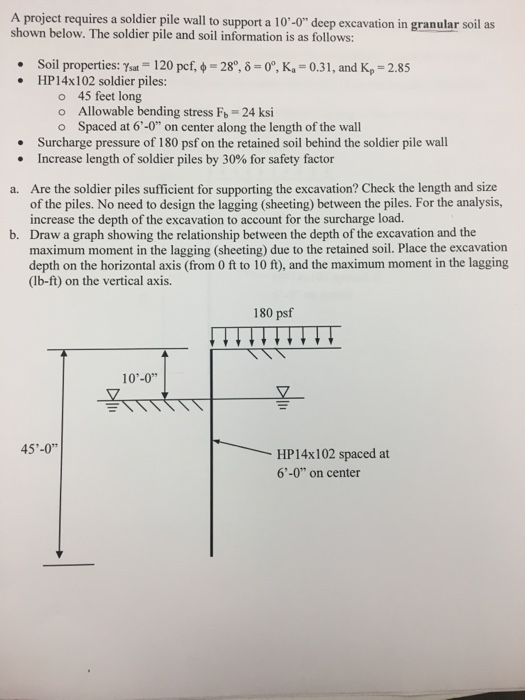

The us army corps of engineers design of sheet pile walls engineer manual from 1994 recommends accounting for a safety factor for the allowable bending stress of 50 50.

Some increase for temporary.

The allowable stress of the material is a function of the material itself.

As for the allowable deflection.

One is the structural capacity of the sheet pile in bending.

While there are differences between these two methods the most important distinction is the interlock.

Stress analysis for the hz az combined wall system based on the allowable stress design method.

It allows the user to easily select a solution based on the bending moments and chosen global safety factor on the steel stresses the user can also prepare a basic material list for a straight retaining wall.

For steel the yield stress f y is used.

However most experts agree that the material.

Application of bending to specific sheet pile sections.

Helmet surface high local contact stresses improper pile guiding applying excessive bending forces obstructions in the ground etc.

For wood an adjusted allowable stress f b is used directly.

Hence f a 50 x ksi of the given steel grade therefore.

A572 grade 50 50 ksi has an allowable bending stress f a 25 ksi s355 gp 52 ksi.

Fy is steel yield strength fc is the 28 day strength of.

F a 26 ksi.

Suggested allowable design stresses sheet piling steel brand or grade minimum yield point psi allowable design stress psi uss ex ten 55 astm a572 gr 55 uss ex ten 50 astm a572 gr 50 uss mariner steel uss ex ten 45 astm a572 gr 45 regular carbon grade astm a 328 based on 65 of minimum yield point.

The second is the effect of the deflection on what you are trying to protect.

Simply calculate the bending moment convert that the the stress in the outer fibers and compare to the allowable stress for the steel.

En 1997 part 1 ec 7 1 for the geotechnical design and en 1993 part 5 ec 3 5 for the steel sheet piles and bearing piles.

For reinforced concrete the stress term r is more complex as it must account for the limit state of both concrete in compression and steel in tension as well as the ratio of.

The stress terms in equations 8 5 8 6 and 8 7 vary.

For example say in a section of plans which has 500 feet 152 m of wall length and a sheet piling length of 48 feet 14 6 m you require a minimum design moment of 75 8 k in ft 28 kn m m.

There are two things to be checked.

It is known in some countries as the allowable stress design asd for the sheet piles.

In piling hot rolled steel sheet pile and cold formed steel sheet pile are two primary methods of manufacturing sheet pile.

The strength of sheet piling to resist bending is a combination of the shape of the section and the material out of which it is made.